Adjustable Speed Drives

Zero-Max designs and manufactures unidirectional and reversible variable speed drives that accept any input with rotating power source speeds up to 2000 RPM. Unidirectional variable speed drives turn in one direction, where our reversible variable speed drives feature an output shaft that can be operated in forward, neutral, or reverse directions. Adjustable speed drive models are available with output in the clockwise or counter-clockwise rotation. We also offer variable speed drives with right-angle gearboxes for lower speed/higher torque applications. The Zero-Max drive is the world's most versatile, economical secondary drive.

Zero-Max Speed Drives deliver the precision and control you require. Contact us to learn more about how Zero-Max can meet your speed drive needs.

A Rugged Design and Precise Speed Control

Externally, Zero-Max Adjustable Speed Drives consist of a rugged, sealed cast case, an input shaft, output shaft, and adjustable speed control. Output shaft speed is regulated precisely and easily through a control lever with a convenient locking mechanism or a screw control to hold speed at the desired setting.

-

Compact and easy to handle.

-

Simple to install. No special wiring or training.

-

Easy to operate with lever or screw control. Repeatable

-

Use adjustable speed drives anywhere on machine. Accepts input to 2,000 RPM. Ideal secondary controller.

-

Delivers constant torque throughout the speed range.

-

4:1 speed reduction. Drive is often usable without additional speed reduction.

How Zero-Max Variable Speed Drives Work

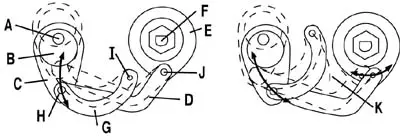

The general principle of operation of Zero-Max Adjustable Speed Drives gives infinitely adjustable speed by changing the distance that four or more one-way clutches rotate the output shaft when they move back and forth successively. The number of strokes per clutch per minute is determined by the input speed. Since one rotation of the input shaft causes each clutch to move back and forth once, it is readily apparent that the input speed will determine the number of strokes or urgings the clutches give the output shaft per minute.

For example, with four clutches working in series and an input of 1800 RPM, the output shaft is urged 7200 times per minute (1800 x 4) or 120 times per second (7200 ÷ 60). If the input speed is dropped to 900 RPM, the shaft is urged only 3600 times per minute and the maximum output speed will be cut in half.

At any point along arc (K) a different output speed is produced because the direction of throw of the connecting rod is altered from vertical (Figure 1 zero RPM position) toward horizontal (Figure 2 maximum speed position), varying the length of the strokes the main links deliver to the overrunning clutches.

Reliable, Low-Maintenance Variable Speed Drive Gearboxes

Variable speed drives are ideal for users and original equipment manufacturers. A low-cost, proven design has resulted in more than 1,000,000 speed drives sold.- Ideal for dancer applications / constant speed changes.

- Leave drive at one setting. No daily speed cycling.

- Accurate speed holding. No "wear-in" period / constant speed operation.

- Goes to zero output. Ideal for use as a clutch.

- Simple maintenance. Factory lubricated.

- Sealed housing. Use in most atmospheres. Can be mounted in any position.

- Versatile shaft / control / motor options.

- Infinitely adjustable. 0-400 RPM speed range with 1800 RPM input.

Variable Speed Drive Accessories and Optional Features

Zero-Max offers drive accessories and optional variable speed gearbox features to help you achieve the exact performance characteristics you desire:

-

For Model E and JK Drives, a selection of gearheads and motors is available.

-

For Models Y, QX and ZX Drives, C-Flange adapters are available for connecting customer-supplied motors to the drive you selected.

-

Lever control is standard on all adjustable speed drives. Optional controls include screw control, extended screw control, extended lever control, extended control shaft, plus flatted and drilled control levers.

-

Direction of output rotation must be specified and is independent of input direction. Model numbers ending in "1" are CCW output, "2" are CW output, and "3" are reversible.

Versatile Speed Control for All Applications

Zero-Max adjustable speed drives operate as primary or secondary drives and are available with several control options and shaft arrangements. Adjustable speed drive applications include:

-

Textile machinery such as looms

-

Food processing machinery such as hamburger presses

-

Agricultural machinery, including grain dryers and seeder drives

-

Printing presses utilizing high-speed sheeters for stacking finished sheets

-

Metalworking machinery

-

Packaging systems, automated sewing systems, conveying and specialized machines

More than 70 Years of Manufacturing Expertise Make Zero-Max a Trusted Name

Over a half-century of manufacturing experience has made Zero-Max today’s leading manufacturer of adjustable speed drives. Zero-Max began when inventor Sterling Stageberg designed a mechanical adjustable speed transmission drive for automotive windshield wipers. His design allowed a variable drive output speed from a constant input from zero to maximum (thus, Zero-Max).

Explore our variable speed gearboxes and variable ratio transmissions to view product specs or contact us to discuss your application. We offer standard and custom or modified solutions to meet your speed control needs.

Choose an industry below for application-specific examples of how our Adjustable Speed Drives help you achieve better precision and control.